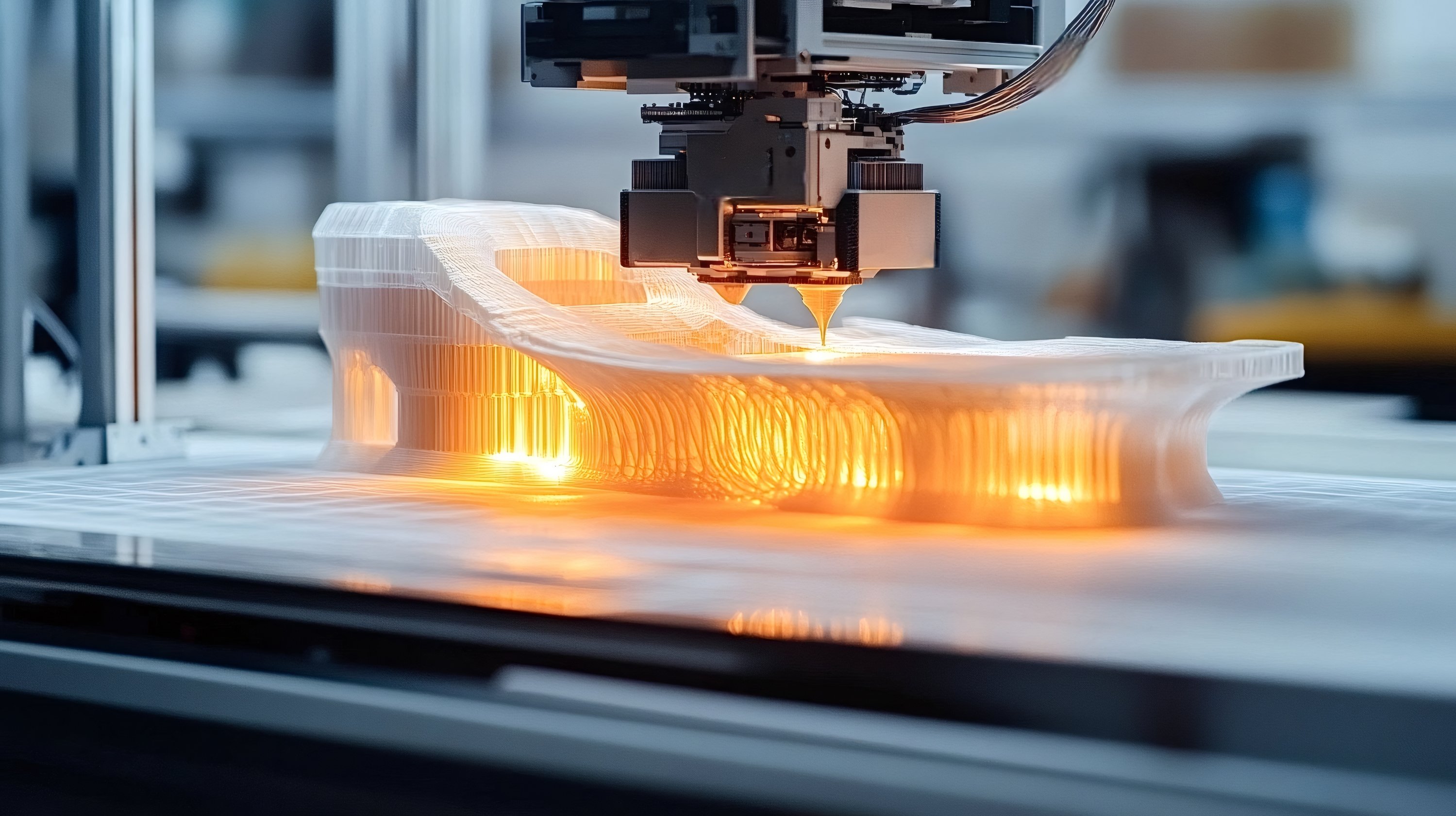

Develop monitoring solutions for real-time assessment of the thermo-mechanical profile within the manufacturing piece & early estimation of the final quality.

Add3DSense

Partner Call open until: Q4 2025

Project Start: Q2 2026

Goal of the project „Smart In-Situ Sensing and Real-Time Monitoring for Quality Prediction in Additive Manufacturing” is the development of advanced algorithms for reconstructing the full temperature / strain profile within the workpiece during the printing / manufacturing process. The reconstruction will be based only on available scarce sensor data and knowledge on the individual printing geometry.

Advantages: Detailed monitoring as basis for

- fast process parameter estimation to increase the printing efficiency

- error correction measures to improve print quality of each individual part

- early estimation of final part quality

- early detection of thermal anomalies to avoid defects like warping, delamination, uneven cooling, etc.

Approach: The in-place sensor infrastructure is enhanced with a combination of our thermal simulation workflow & physics-aware ML-models.

- No additional sensing infrastructure needed

- The use of an automatized simulation workflow removes the need for collecting extensive high-quality measurement datasets for data-hungry AI models

- The combination with ML techniques removes the need for extensive calibration of the simulation models and allows the usage of simpler low-fidelity models

- We setup & generate the training dataset based on domain knowledge from the partner

- We develop, train & evaluate suitable physics-aware ML models

Challenges:

- Development of simulation workflow for specific use case / printing / manufacturing technique

- Selection of suitable randomization parameters (e.g. geometry representation, print path, environment conditions) for generation of ML dataset

- Generalization of monitoring solution for arbitrary printing geometries

Expected results

SAL as one partner for the whole workflow:

- We help you develop a first-time-right additive manufacturing solution with our advanced thermal monitoring

- Reduce cost, material waste and energy requirements

- We optimize the model for deployment on an embedded device (e.g. microcontrollers)

- We validate the developed solutions in cooperation with the partner based on experiments on partner site